Nanomachines. Generic "factories". Handwaving. These are the cop-outs used by science fiction writers to bring a Mars colony's industrial base into existence. But the reality isn't so pretty. In this diary, we will examine the industrial requirements of such a colony, compare it to past colonization efforts, and look at potential solutions.

Part One: Beyond The Space Elevator: A Glimpse Of Alternative Methods For Space Launch

Part Two: Where Will We Begin?

Part Three: Who Will Bring It About And Why?

Part Four: The Industry Dilemma

Historical example

In Dyson's comparison between interplanetary colonization and historical colonization expeditions, he comes up with the cost of renting and provisioning the Mayflower of 1,500 to 3,600 pounds, with an expected cost of around 2,500 pounds. If you convert this into today's dollars by comparing wages at the time to today's wages, that's $22M ($170,000 per passenger, counting crew). If you compare agricultural prices, it cost $600,000 ($4,500 per passenger).

Only half of the people who departed England survived the voyage. The passengers arrived in the new world with the ship's provisions -- food, enough clothing to nominally last seven years, furniture of all kinds, cutlery, earthenware, rifles, lead for bulletmaking, gunpowder, and countless tools -- hoes, shovels, rakes, axes, sickles, adzes, hammers, mallets, nails, etc. Even with all of their preparation, they began their survival in the harsh new world by robbing food and supplies from an abandoned native village, and continued the theft for much of the early colony's history.

The overwhelming majority of their supplies from the colony came from "bootstrapping". They cut down trees and hauled logs to build houses and fortifications. They gathered plants to make rope and thatch for houses. Construction began in late December and was finished by February. The next year, they began planting fields. They were aided by local knowledge taught to them by the Wampanoag tribe. The colony, while still trading with England, was nearly self-sustaining after their first harvest, and certainly by the very successful subsequent harvest in 1621. The colony as a whole could have been completely self-sufficient, had circumstances required it, within one to two decades.

The entire "essential" tech base required of the early European settlers to the Americas consisted largely of the following:

- Charcoal, the key element of much of 17th century industry, was produced in charcoal kilns. These were extremely large, carefully built bonfire layouts of coppiced wood which were then buried in thick layers of dirt, with only small openings for oxygen to enter and exhaust to leave. They would bake themselves for long periods of time, the ash would be removed, and the charcoal would then be sold.

- Gunpowder was produced from a mixture of charcoal, sulfur, and saltpetre (potassium nitrate). Sulfur is produced simply by heating sulfur-rich soil; the "brimstone" drains out. It can also be found pure or near pure in geologically-active areas. Potassium nitrate is produced by aging manure and urine under a roof, running it through hardwood ash, boiling it with turnip halves and oxblood to remove the organic matter, and drying it. The process of turning the ingredients into a gunpowder that will explode rather than just burn took great skill.

- Bullets were produced simply by pouring lead into iron molds and letting it set; this was a simple enough task that anyone could accomplish it. Most lead ores were likewise relatively trivial to deal with; raised to a sufficient temperature, the molten lead drips out. No fluxing agents are required. Galena is the primary lead ore and is one of the most abundant and widely distributed sulfide materials; there are few places in the world where it cannot be found.

- Pig iron was produced in a clay or brick kiln, fired by charcoal, and pumped by a bellows. The raw pig iron poured out through the bottom in guided channels.

- Wrought iron was produced in a finery forge, where the pig iron would be remelted to oxidize impurities, hammered to consolidate it, and worked into a bar.

- Blacksmiths, such as Richard Sears, arrived on the Mayflower itself, as they were essential in the operation of a colony. The blacksmith's workplace was a wood-framed building with a clay or brick kiln, fueled at the time by charcoal. Bars of wrought iron were hammered into shape over an anvil and repeatedly heated until forming the desired tool, at the blacksmith's discretion.

- Miscellaneous "essential" tasks, such as farming, milling, and woodworking need little explanation.

We know that smithing, charcoal production, and bullet manufacture were done in the early colony; however, the timing of the manufacture of gunpowder, the production of saltpetre, and the mining and processing of sulfur, lead, and iron ore are unknown. Records don't become well established until a few decades later -- for example, we know that in 1650, Governor John Winthrop was granted a license to develop mines of lead, copper, and tin near Middletown, Connecticut. While mining and production of these resources could have begun essentially immediately had prospecting data been available, the ability to trade with England decreased the importance of these activities in favor of the pursuit of defense, securing stable food production, and improving the colonists' quality of life.

The entire "essential" tech tree of a 17th century colony could be run by several dozen individuals. The entire mining and "industrial" base could usually be established within a single region under which trade by foot or ox cart was sufficient. If not, a colony willing to import its gunpowder, lead, iron or even whole tools could be established with minimal effort. As noted above, the passengers plus all of their equipment to bootstrap the colony could be shipped to the new world for prices that, while expensive, were not prohibitive.

Native Americans colonized the New World with an even simpler tech base. They relied less on technology and more on bootstrapping. The entire infrastructure around steel and gunpowder was omitted in favor of hand-knapped tools.

Let us contrast this to a Mars colonization mission. On Mars, there is no bootstrapping. There is no boot. There are no plants. There are no animals. There is no air. There is no water. There are no natives. There is no radiation shielding. A colonist on Mars, therefore, is reliant on the a wide variety of modern technology merely to survive. So their "bootstrapping" requirements are, to be blunt, to recreate a large subset of our entire technology base. Mind you, they only need most products in low volumes.

What's the problem?

Let's just pick a single essential part. Let's say, a part for some industrial process that deals with high temperatures, so it must be made from an alloy that retains significant strength at those temperatures. Such alloys are generally a combination of iron, nickel, and titanium, plus trace parts of other elements. Let's just look at one path: iron.

On earth, iron is made in a blast furnace. Ore and coke are dropped into a furnace from the top while oxygen, purified from the air, is injected from underneath. The primary fluxing agent is crushed limestone, which not only creates a slag which protects the molten steel from corrosion, but removes silicon and phosphorus. While this may be where the textbook description of the process stops, that's just the tip of the iceberg. For example, there can be many more types of fluxing agents added. A common one is fluorspar, which increases the reaction rate and yields a higher quality product. A source of magnesium is needed to eliminate sulfur. And so forth. Argon or nitrogen are often bubbled through the steel to ensure proper mixing. And there's a huge part count at every step of the way -- everything from fan belts to slag skimmers. Every last one of these parts has a finite lifespan, its own tech tree, and cannot be readily bootstrapped (with a few exceptions)

Now lets see what happens when we place this steel mill on Mars. There's no coal or oil on Mars from which to make coke. On Earth, most calcium carbonate is deposited from or in conjunction with marine microorganisms, which aren't an option for Martian sources -- although Mars likely has at least some sources of calcium carbonate, and dolomite (calcium magnesium carbonate) can be substituted. There's no oxygen to oxidize the slag, but you still need to produce it to eliminate the impurities. There's also virtually no atmosphere to dump waste heat to, and there's electrostatic dust interfering with your operations. The various fluxing agents need to be gathered from points which are unlikely to all be found in the same area or even the same region of Mars (assuming you can find deposits of them all). And, of course, you have to keep importing parts for to keep everything running. You need oxygen to feed in, which doesn't exist in the air. Argon and nitrogen are far rarer on Mars than on Earth. On and on down the line.

Let us look at the Linz-Donawitz (BOS) process on Mars. Preheated iron ore left over from our sulfuric acid process (below) is burned with methane from the Sabatier process (further below) and small amounts of oxygen (from water electrolysis) to produce high carbon pig iron, which pools at the bottom of the blast furnace (the "ladle"). No pretreatment is necessary, since we will be dealing with low sulfur iron ore, thus sparing us from the necessity of magnesium production at this point. As is normal, a watercooled lance (which will require an extensive cooling setup -- probably water-evaporative) injects oxygen into the ladle to raise the temperature as it burns away the carbon. The standard fluxes are then added: burnt lime or dolomite. Optimally, the chemistry of the steel is analyzed at this point, and any adjustments to its composition are made. The ladle is dumped into another vessel, where any alloying agents are added in. Gasses are bubbled for mixing. The reaction would almost certainly have to take place in a pressure vessel for proper recovery of gasses.

Note that we're not bothering to go into casting or machining yet.

So now we've gone from one requirement -- a high temperature alloy -- to the following:

- Nickel

- Titanium

- Other alloying agents for the part

- Crushed calcium carbonate

- Calcium carbonate roaster

- Fluorspar

- Other fluxes.

- A whole steel mill's worth of parts

- Low-sulfur iron

- Oxygen

- Other gasses, compressed

- Water (consumed unless a recovery circuit is present, which presents its own challenge)

- Radiators

Each of these have their own requirements trees -- often tremendous. Even the simplest of them, such as "crushed calcium carbonate", can have way larger trees than you'd expect. Ignoring the prospecting stage, for a simple crushed mineral, you need mining equipment, bucket loaders, conveyors, separation processes (float baths, froth separators, etc), ball mills, and often with various leaching and rinsing stages along the process. Even ignoring the electronics systems and their mind-boggling number of widely varied components, you're talking tens of thousands of parts that need maintenance and a wide variety of bulk consumeables.

I noted that I'd discuss a little bit about the link between sulfuric acid and iron on Mars. On Earth, we get our sulfuric acid -- an utterly critical industrial chemical -- from the petrochemical industry. Since there are no natural petrochemicals contaminated with sulfur on Mars, there is no sulfuric acid coming from it. However, there's an equivalent "problem" that can yield sulfuric acid: that of sulfur-contaminated iron. Sulfur seems abundant in Mars's iron-based minerals examined thusfar. An earlier process for making sulfuric acid bears a natural link to Mars-based iron production and should be integrated into Martian blast furnaces.

Powdered iron sulfates, when heated to a degree in the presence of oxygen and steam, absorb progressively more oxygen before outgassing sulfur trioxide. The sulfur trioxide combines with the steam and enters a condenser lined with many radiators/heat exchangers, where it precipitates out as concentrated sulfuric acid. The input iron sulfates are cycled through in a continuous process, with new sulfates added into the reaction chamber at the top and hot iron oxide removed from the base (which can then be sent on to steel production).

Potentially, raw, highly sulfur-rich iron ore could be ground in a ball mill, dumped into the reaction chamber, and baked; while some heat would be wasted heating non-sulfates, it would pass straight into steel production from there, utilizing the gained heat. Note that the entire system, from the moment that the ore enters the reaction chamber, should be lined with acid-resistant materials, such as lead. Steel production and sulfuric acid production could exchange heat, potentially having an single open-ended process which consumes electricity, ore, water, oxygen, calcium carbonate, other fluxing agents, and methane, and produces molten steel, slag, concentrated sulfuric acid, and carbon dioxide.

Note that we've just added a new element to our maintenance requirement: lead. Indeed, as you trace back the tech trees for everything required for a Martian colony -- power, metals, ceramics, plastics, clothing, electronics, food and fertilizers, lubricants, hydraulic fluids, solvents, abrasives, medicine, personal items, oxygen, CO2 scrubbers, rocket fuels, and so forth -- even after optimizing your technology base to reduce part and material counts, you end up with hundreds of thousands to millions of parts, comprised of tens of thousands of chemicals, comprised of over a hundred elements.

Indeed, while some elements on the periodic table can largely substitute for one another -- for example, most rare earths have similar properties -- most cannot. Nothing but gallium works for its various gallium arsenide and gallium nitride semiconductor applications. If you don't produce niobium, you have to use much lower temperatures to produce superconducting magnets, greatly increasing the difficulty. Nothing approaches hafnium's ability to give up electrons to the air, making it near universal for arc welding, and its addition to alloys is second to none for preventing corrosion in rocket engines. Solid-state x-ray or infrared detectors, or the only so-far proven mass-produceable thin-film non-silicon solar panels? You'll need tellurium. In fact, if you want thermoelectrics that don't suck, you'll need both it and bismuth. Want your high-carbon steel to be strong enough for tooling, or to be able to be bonded to titanium -- or perhaps you need a temperature-selective IR shutter? Vanadium is the key. If you're doing almost anything with nuclear physics (or half a dozen other fields), you're going to need beryllium.

On and on it goes. Each of them needs their own distinct and elaborate process to produce.

Or do they?

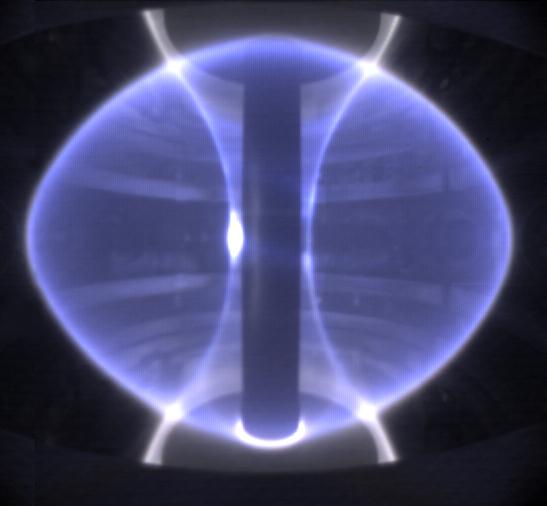

Plasma centrifuges to the rescue?

It should be apparent by now that the key to a viable Martian industry is the consolidation of as many production processes as possible into as little machinery as possible. In terms of resource extraction, there is one fledgling technology that could play a huge role: plasma centrifuges.

A plasma centrifuge starts with incinerating your source material in a high power electric arc. A combination of electric fields, magnetic fields, and optionally RF keep the plasma trapped and rotating at ever-higher speeds. The centripetal force weighing heavier on heavier ions helps overcome their natural tendancy to fully mix. The plasma is then allowed to collide with targets based on its distance out or the heaviest elements are allowed to escape, cool, and deposit, then successively lower energy elements. Plasma centrifuges, hence, separate not only elements, but also isotopes, based on their atomic mass.

How good are plasma centrifuges? Well, they're not perfect, but they're not bad. On similar-mass elements (a few percent difference), they usually get a separation factor of 1-2. This is clearly not acceptable for most tasks, but can be boosted with repeated centrifuge stages, multiple passes, or through the use of countercurrent centrifuges. On the other hand, plasma centrifuges were already exceeding a factor of 140 in separating the hydrogen and oxygen in water back in 1984.

The potential of plasma centrifuges for Martian resource extraction are clear. Unlike with a gas centrifuge, where you must first convert your resource to a gasous form (which can vary depending on the elements), every element in an ore can readily be converted to plasma. The separation factors are higher than in gas centrifuges. The additional isotopic separation is an added bonus invaluable to any Martian nuclear industry and academic research. Ore goes in, and what comes out is deposits of every element contained within that ore.

So we're saved, right? Well, not quite...

Plasma centrifuges are not without their faults, however. It should be clear that by having plasma collide with a target, you're not only depositing it, but also damaging the target. The targets must be continually recycled. Different elements have different chemical properties, requiring different capture methods. Staging may be required to get sufficient purity. Some elements are not solid under reasonable temperature and pressure conditions, and hence need more complicated collection methods.

One big problem is that a great deal of energy is needed to run a plasma centrifuge to yield a small amount of output. The centrifuge itself, additionally, will likely be a large object compared to its throughput. The exact severity of these problems will not be known until an actual prototype for Martian mineral production is developed, but the problem needs to be analyzed.

One can easily say, "just build more power infrastructure and more centrifuges", but therein lies the conundrum. That argument relies on saying to build more of something, when the equipment used to make the materials for construction maintenance is not yielding much of the materials to build them. Likewise, building more and bigger centrifuges means more materials and more maintenance. It should become apparent that without significant advances, plasma centrifuges will be of prime use in extracting many lesser elements from ores -- alleviating the need for mines and specialized processing equipment for each element or small group of elements. However, the production of bulk materials -- construction metals, construction ceramics, greenhouse glazing, water, oxygen, and fertilizers -- must be done through specialized processes. These, and their bulk feedstocks, must be provided directly. Hence there still will be extremely large production infrastructure required.

A second problem with any approach is that not every resource is found everywhere. A Mars colony will rely on minerals mined from all over the planet. How can one ship these minerals back to the primary colony, where all of the production infrastructure will exist in one place?

- Driving: One could propose to drive the goods over these distances. However, that will involve a great deal of wear on such a vehicle and involve traversing tremendous hazards, with extremely long transit times.

- Rail improves upon this, but requires an implausibly massive amount of infrastructure construction for an early colony.

- Rocketry could certainly do the trick, but a rocketry industry is both quite complex and extremely resource inefficient. On a planet like Mars, with very limited production infrastructure, inefficiency equals death.

Instead, it seems that a #4 is in order:

- Ballistic shipment of resources. Coilguns and railguns are excellent choices on the surface of Mars. Mars' minimal atmosphere (0.007 ATM) and reduced gravity (0.38G) mean that goods can be launched great distances with smaller hardware and energy requirements.

Nonetheless, there still will be a significant associated cost with each launch, in terms of wear, energy, and launch containers. Hence, the target ore should be separated from the tailings at a bare minimum before transport. The goods will crash down in a target zone in a destructive but controlled fashion, be collected, and loaded onto transport. Over time as the colony grows, more industry will grow around each mine and rail will begin to link the closer mines and cities to each other.

The third big problem is that industry isn't about producing elements. It's about producing products. And while some products are made of pure elements, most are made of alloys or compounds.

Compounds

Raw elements are generally excellent components for initiating chemical reactions, as they tend to be highly reactive. Many are useful in their own right. But for the purposes of a colony, that's not enough.

When it comes to forming compounds, probably no industry is more complex than the petrochemical industry. On Mars, one is immediately presented with a quandry: plastics and a wide variety of other petrochemicals are completely essential to modern technology, but there's no petroleum on Mars.

Thanfully, there are a few solutions. Allow us to trace back the creation of a single petroleum compound -- say, acrylic for Martian greenhouses. Why acrylic? There are dozens of types of plastics (and many varieties of them); acrylic is very light-transparent (even moreso than glass) - it's sold as Plexiglass, Lucite, etc (not to be confused with polycarbonate - Lexan). This actually a relatively easy case compared to many other materials you'll need on Mars.

Plastics like acrylic are polymers - chains of monomers. Acrylic is polymethyl methacrylate (PMMA). First, of course, you're going to need a petroleum source. This takes a variant of a process first used en masse by the Nazis in World War II - the Fischer-Tropsch process. The variant is called the Sabatier process; while Fischer-Tropsch uses carbon monoxide as its carbon source, the Sabatier process uses carbon dioxide plus additional heat energy. Either are workable solutions on Mars. While you can optimize them to produce chemicals in a desired weight range with specific catalysts, temperatures, and pressures, it tends to produce a fairly random mix of low weight hydrocarbons. So, you need to distill the hydrocarbons.

Lets back up a minute - hydrogen, carbon monoxide? Hydrogen is easy - electrolysis of water, although note the high electricity requirements (if you have a high temperature nuclear reactor, you can thermally split it as well). There's plenty of CO2 on Mars, but not as much CO. Thankfully, you can strip an O from CO2 with hydrogen via partial Bosch reaction, or you can produce it through partial combustion of most carbon compounds (such as graphite from the Bosch reaction). To get that CO2 that is the root source of our carbon, you need to highly compress the Martian air (with a multistage compressor), then chill it to separate out the CO2, then reheat the CO2. One should use a a thermally efficient process involving heat transfer to other working fluids wherever possible.

With either the Fischer-Tropsch process or the related Sabatier process, we then have to build a large chunk of an entire oil refinery -- everything from distillation towers to isomerization plants. However, sulfur removal processes and most crackers should be able to be omitted.

Now we need to form MMA, the PMMA monomer. This can be made through esterification of methacryllic acid (2-propenoic acid) with methanol. Now we have two chemicals that we need to produce. Methanol

is easier -- reacting CO with H2 on a copper/zinc oxide/alumina catalyst at high pressure and moderate temperature produces it (of course, as with each process here, you need to deal with heat exchange, waste products, tailings, etc). Methacryllic acid (CH2=CHCOOH) is made from either ethylene+H2O+CO at high pressure and moderate temperature with a nickel bromide catalyst, or from propylene with a little oxygen and steam over a molybdenum catalyst at fairly high temperatures. You can also make it from acetone, although that's indirect, so we won't cover that here. The higher the temperature, the more important it is that you do heat recapture.

Now we must consider how to polymerize the MMA. In general, you need an oxidizer; peroxides work well. Different catalysts and oxidizers will produce plastics with different properties; however, even trace amounts of O2 should work to some degree, although O2 in too large of quantities is an inhibitor.

Now we have PMMA. It needs to then be formed into panes of resonable thickness and large size before it sets, and then be allowed to set. Then you have to take the molded acrylic, working in pressure suits (highly constraining), and position them with cranes. Then you have to join the fragments together with superglue (cyanoacrylate synthesis is left as an exercise to the reader). Then you need to test-pressurize it. Your whole greenhouse glazing will need brushes that rotate around it to clean off the accumulating dust.

If the last section of this article left you with some optimism that colonization might be easy, this section likely ruined that. Every last step in the above requires an elaborate piece of infrastructure full of pipes, valves, electronics, heaters, heat exchangers, pumps, motors, and so forth. And as much as we would like to say, "Okay, we'll just use one or two plastics", that's not an option. Different plastics have very different properties, preventing a "one plastic fits all" production strategy.

Rayon is used in clothing blends. Phenolic plastics (like bakelite) are used in some circuit boards, and it can be used non-optimally in hard-plastic applications. Polystyrene not only makes a good packing material when foamed, but is an good hard plastic. PVC can be made into an excellent hard or soft, durable plastic which is self-extinguishing. Nylon can be used in clothing and heavy-duty plastic parts (gears, bushings, et al). Neoprene is a rubber replacement, as is styrene-butadiene rubber. Polyacrylonitrile (PAN) is another resinous/rubbery plastic akin to neoprene, used in carbon fiber production. Acrylic is used in paints, clothing, and perhaps most importantly, their transparency makes them suitable for glass replacements ("Plexiglass", "Lucite") - essential for direct solar-powered Martian agriculture. Polycarbonate is another suitable material -- more impact resistant, also with good thermal IR blocking properties and high transparency, but which blocks instead of transmitting UV. Polyethylene (HDPE and LDPE) is flexible, durable, and cheap, used in everything from tupperware to plastic wrap; similar plastic polypropylene shares its properties. Polyurethane can be cast into hard, abrasion resistant parts or used as a sealant; its foam is also an excellent padding and insulating material. Teflon is an invaluable polymer in some parts of industry due to its incredible resistance to chemical corrosion. Teflon coated containers are, for example, the only containers that can contain fluorine gas for an indefinite amount of time (although others have long lifespans). PET is used in the synthetic fibers polyester, dacron, and terylene; due to its resistance to fluid permiation, it is used in plastic bottles and its film (Mylar) has a wide range of applications. Kevlar is one of the strongest and most heat-resistant plastics in existence, although is quite expensive due to having to be spun from a concentrated sulfuric acid solution and having relatively complex monomers.

Epoxies -- needed for both their ability to bond objects together and their ability to form composites -- are simply thermoset plastics in which the catalyzing agent has not yet been added to the monomer (polyurethane is a common choice). Composites are plastics formed around a matrix of another material, and optionally pressed and baked for better performance. That matrix is usually either fiberglass (a spun ceramic), boron nitride fiber (made from borazine or cellulose), kevlar (spun from a sulfuric acid bath), or carbon fiber (anoxically heated PAN fiber) cloth.

Plastics frequently contain other chemicals to alter its properties. For example, hexagonal boron nitride increases thermal conductivity while decreasing electrical conductivity, and reduces surface friction with metals. There are countless plasticizers, UV blockers, free radical scavengers, etc added to plastics made from all kinds of different materials.

Note that plastics are merely one class of petrochemical products.

This daunting task can only be resolved by a tremendous and costly amount of engineering work done in advance of the mission. Careful engineering could reduce the required number of plastics down to a couple dozen from the thousands available on Earth today. However, if a colony were to be built to the spec of whatever is available here on Earth today, such colonies would not be maintainable or expandable on Mars. Colonization must, therefore, wait until as much engineering is done as possible. It is essential that engineers likewise design production infrastructure to be readily reconfigured to produce different chemicals, in a manner that is fully automated or requires a minimum of human intervention. However, this poses challenges greater than anything we have described thusfar.

All in all, the engineering efforts involved in this stage will involve hundreds of thousands to millions of engineering man-years and hundreds of billions of dollars. And we're not even done yet.

Turning chemicals to products

Just like elements != requisite chemicals, chemicals != finished products. Thankfully, this situation, while nontrivial, isn't as onerous as establishing a chemical industry.

To produce bulk blocks, sheets, and other such shapes, metals and plastics must go through a casting house. In here, they are placed into molds and/or extruded. Often the process of casting involves heat removal, which is much simpler on Earth than on Mars. Many casts are temporary and made of materials such as ceramics which are broken off the part when it is removed. Other casts, especially when dealing with plastics, require coatings to prevent the plastic from adhering, some of which may be consumed in the process. Some production processes are continuous, while others are in batch form.

One fortunate aspect available to a colony is reuse. A single metal casting house can generally be used for casting multiple types of metals, so long as the molten metal can be brought to the casting house fast enough (or vice versa). The similar can apply to plastics, albeit with different linings.

Simply setting the materials is not enough. Thin sheets and fibers must be assembled into reels; the core is a recycleable consumeable. Large objects must be hoisted by crane into stacks on pallets or rail beds. The various casting houses will need to manufacture are various sizes and shapes/thicknesses/lengths of sheets, slabs, ingots and blooms, films, tubing, I-beams, and so forth. This means many hundreds of raw materials for each part.

Fortunately for a colony, high volume is only needed for certain parts. The incredibly broad diversity of parts needed for expansion and maintenance are for the most part low volume. This leads to each of their parts being able to be produced through a variety of CNC machines and 3d printers. In a CNC machine, a large chunk of the material to be worked is fed in and the computer carves the part. An example of the impressive capabilities of such machines can be seen here. 3d printers work in the opposite manner, building up an object one layer at a time, often inside a structural matrix.

Note that these technologies are generally known as rapid prototyping -- emphasis on the "prototyping". Their time per unit, consumables, and energy consumption are much higher than that over dedicated production hardware. But an early Mars colony simply cannot dedicate a piece of tooling for every part that it needs. That will only come far down the road, when the demand supports the volumes.

Note that most components are not a single object; they are themselves made up of multiple parts. Multi-axis robots will be used to the extent practicable, but some human work may still be required. Note that on a Mars colony, human labor will be tremendously expensive since the resources to keep them alive are all so difficult to come by.

The final stage is distribution and installation of parts. While distribution may be all or completely automated, and installation may in some cases be supported by machinery, the great number and diversity of parts will generally lend itself to human installation for most of them.

The silver lining

There is a silver lining to all of this.

First, the great engineering expense -- a total of hundreds of billions of dollars -- is met with great spinoff potential which, while likely not paying for all of the cost, may pay for a large chunk of it.

Secondly, the colony need not be immediately self-sufficient. Things like electronics and solar cells can be expected to be imported for many decades after the colony is first manned, which ideally would not begin until decades after the engineering began in order to ensure that any hardware landed is compatable with the production capabilities that the colony will gain. But once the materials and production hardware that will be available to the colony is well known, the production and delivery of the bulk construction materials has begun on the planet, and the tools for assembly are in place, humans can begin to colonize the Red Planet -- fully independent or not.

With each decade, the colony's required imports will drop by an order of magnitude. And ultimately, the necessary connection with Earth will be severed. When that day arises, we will truly be a two-planet species -- ready to spread to the stars, to better our lives and to become immune to extinction except by the slow process of the universe we know as Heat Death.

Should we achieve this fate, may we always be benevolent as we would wish others to be to us -- never terraforming away life just because it's simpler than us, and respecting the rights of any species we encounter.