Using photomasking techniques similar to those developed for producing integrated circuit chips, scientists at MIT and Harvard have developed an inexpensive way of Creating 3D brain tissues in a lab dish, using brain cells from the primary cortex of rats, opening up new areas of brain and neural research.

(Graphic credit: U. Gurkan et al./Advanced Materials)

The new technique yields tissue constructs that closely mimic the cellular composition of those in the living brain, allowing scientists to study how neurons form 3D connections and to predict how cells from individual patients might respond to different drugs.

The work also paves the way for developing bioengineered implants to replace damaged tissue for organ systems, according to the researchers.

“We think that by bringing this kind of control and manipulation into neurobiology, we can investigate many different directions,” says Utkan Demirci, an assistant professor in the Harvard-MIT Division of Health Sciences and Technology (HST).

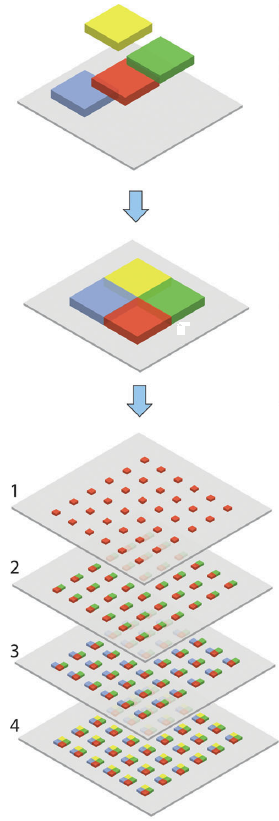

Other researchers have been growing other organ tissues in petri dishes, but other organs are more homogenous than the brain. The "incredible heterogeneity" of the brain presents special challenges as the brain contains intricate interconnections of diverse cell types, such as inhibitory and excitatory neurons, glia cells, and other support networks. This new technique allows sequential layering of these different types of cells, embedding them in plastic gel screens similar to overhead projector sheets rather than the vastly more expensive scaffolding grids used in integrated circuit technology.

Researchers have managed to get the resolution of their gel layer tissue cubes down to a width of 10 microns, which is similar to the size of a body cell. Their current goal is to create a cubic millimeter of brain tissue consisting of 100,000 cells with 900 million connections. If we pause and think about that for a moment, we glimpse just the tip of the iceberg of the astounding complexity of a full human brain.

In the long term, the researchers hope to gain a better understanding of how to design tissue implants that could be used to replace damaged tissue in patients. Much research has been done in this area, but it has been difficult to figure out whether the new tissues are correctly wiring up with existing tissue and exchanging the right kinds of information.

In future work, doctors may be able to take brain cells from patients with certain neurological disorders and turn them into stem cells that can be grown in these 3-D lab dishes to help develop drugs targeted to these disorders much more quickly than would be the case if experiments had to be done to brain cells still attached to humans, where research is limited by human research ethics committees. (ho, ho, ho! I"m joking here, but this research does raise the question of at what point do we need to worry about networks of brain cells "experiencing pain?" )

Maybe they need to hook these lab dish brains to some eyeballs, legs and vocal chords so they can do input-output tests. Of course, we need to start to prepare ourselves for the day one of these new lab dish creatures talks back and turns out to be smarter than we are. At the rate we are seeing such extraordinary advances in brain science this day may be sooner than we expect.

6:49 PM PT: My goodness, I don't know why I didn't see this coming, as it is not too hard to imagine. I should have known this wouldn't be the first case where the brain beat the penis out in being the first organ to achieve market penetration in the stiff competition for bringing new 3-D printing technology to market application.

If mankind develops an exciting new technology for "printing out" artificial organs which organ do you think will come first? So to speak.

3D Penis Print-Outs From 3DEA Are The Future Of Dildos As the authors suggest, with Christmas coming so soon what better gift to stuff someone's stocking with.

3DEA, a pop-up 3D printing store in New York City, is offering customized dildos formed from laser scans -- and 3D print-outs -- of customers' penises.

The process is pretty simple: After a "quick tutorial on how to perfect your scan," the excited buyer enters a scanning booth, where ShapeShot technology snaps some images of the patron's manhood, then uses those images to print out a 3D model. They send the model to New York Toy Collective, where sex toy professionals use the print-out to create a one-of-a-kind dildo.

Sure, customizable dildos have long been available via plaster casts, but as Otto Massimo of Fleshbot (WARNING: EXTREMELY NSFW link) points out, the laser technique provides quite a few benefits.

For one, the subject only has to maintain an erection for about three seconds, rather than the extended period of time required for a plaster cast.