Someday, this disaster will be over. Someday, the world will stop deepwater drilling. Someday, the world will wean itself off of oil. Unfortunately, none of those days will come soon enough for most of us. Meanwhile, oil companies will get government permission to drill in deep water using technology that is similar to the package that failed on the Deepwater Horizon.

In this diary, I want to share some documents that bear on the Blowout Preventer (BOP), the fundamental safety device that is the ultimate protection against a catastrophe like the GoM. These documents are not secret. They are publicly viewable on the website of the Minerals Management Service (www.mms.gov).

I warn you that the contents of these serious, industry-supplied presentations and studies will set your hair on fire. They will also prove that the Oil Industry (and their regulators) have been systematically, cynically and stupidly lying to us for decades.

If aircraft had BOPs, the documents linked in this diary would ground every plane in the world.

The Minerals Management Service website is a cornucopia of technical studies, reports, and industry conferences and presentations concerning the operations of the oil industry. When I stumbled on it, I found that any Google search that included "site:mms.gov" brought up all sorts of interesting things. However, in this diary, I am going to reference 3 documents:

The first two are mandatory background reading:

- Reliability of Subsea BOP Systems for Deepwater Application, Phase II DW, Unrestricted version – 1999 - (http://www.mms.gov/...)

- Deepwater Kicks and BOP Performance, Unrestricted version – 2002 - (http://www.mms.gov/...)

[Note that the Deepwater Horizon was built in 2001 and was one of the newer, more capable rigs in the world.]

I encourage you to read reports (1 and 2) - they are long, detailed, fact-filled, technical and convincing. However, while I include and reference some of their figures and tables, I will focus on the 3rd document:

- Arctic Relief Well Drilling: An Oil & Gas Company Perspective, Presented at MMS Arctic Technologies Workshop Anchorage, October 13 - 15th, 2009

Chevron gave this presentation just 8 months ago, It has pretty pictures and (inadvertently) gives a summary of the case against conventional BOP that is utterly damning. Please read it you can. If not, my Cliff Notes are as follows:

--- Setting the Scene:---

Canadian drilling standards for subsea oil wells in the Arctic make, at a minimum, the following demands:

- The driller must have a second drilling ship on standby to drill a relief well in the event of an accident. This doubles the cost of drilling a well in the Canadian arctic.

- The driller must present a drilling plan that allows enough time for the second drill ship to complete the relief well in the same drilling season as the accident. If the Deepwater Horizon accident had occurred in April in the Canadian Arctic, we would still have to wait until August for the oil gusher to cease. In other words, the Canadian standard is our worst-case scenario for the current BP disaster.

Against this background, Chevron's presentation argues for an alternative approach to drilling safety that it claims would allow it to drill without a second drill ship on standby and without having to guarantee that it can complete a relief well in the same year.

--------

Pages 1-4: Chevron reviews the challenges associated with ensuring that a relief well can be drilled in Arctic conditions within the same drilling season. There are lots of bullet points that effectively say how expensive that is, along with the obligatory arguments that it hasn't been necessary in the past.

Simultaneous translation: "Its really, really HARD and nothing bad has happened so far - so you're just mean to make us do it"

---------

Pages 5-14: Chevron argues that drillers will increasingly be pushed into deeper water, where meeting the same-season relief well criteria will be even harder. Its going to cost a fortune. It might even prove impossible. In that case, there would be all that glorious oil just sitting out of reach - mocking us for not having the guts to go and grab it.

Simultaneous translation: "Its really, really, really HARD and EXPENSIVE - that obviously means that gas will soon cost $10/gallon."

---------

Pages 15-18: Chevron has asked Cameron (the Deepwater Horizon BOP-making people) to build a shiny new toy. They call it the "Alternative Well Kill System" (AWKS). Lo and behold it is a bigger, better, smarter Blow Out Preventer (BOP) that is so super fantastic that Canada should just throw away its same-season relief-well standard and let Chevron drill, baby, drill. The AWKS will guarantee to keep everyone safe.

Simultaneous translation: "Me Engineer - You not so much. TECHNOLOGY RULEZ!"

---------

Page 19: Chevron notes that drilling in the Arctic has special challenges. One is that ice movements may force the drill ship to disconnect and reconnect fairly often. That means that the BOP has to be cycled to shear and seal more often. That creates more opportunities for failure. The shiny new AWKS will be specially designed to address this problem.

Simultaneous translation: "Existing BOPs, like the ones used in the Gulf, can fail if there are frequent connects and disconnects. Hurricane season anyone?"

---------

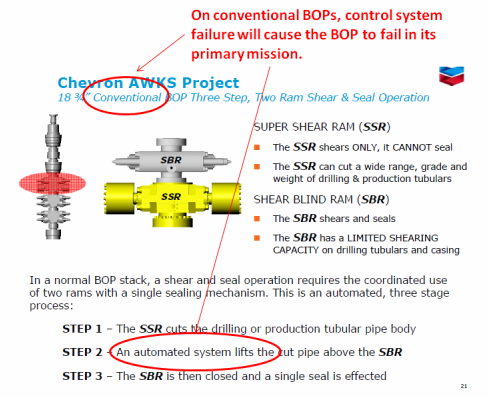

Page 20-21: Typical conventional subsea BOPs are complex devices with a set of stages to control the piping and flow. The typical structure is as follows:

- Top two preventers are 'annualar' rings that are designed to seal tightly around the drill pipe - but not actually seal off the pipe itself.

- The middle two preventers are, respectively, a shear and a seal ram. The shear ram can cut the pipe, but cannot seal against pressure. The seal ram can seal - provided that the pipe has been cut and jacked up out of its way. The two rams work together in an automated three-step sequence to cut the pipe, lift the pipe, and seal the well.

- The bottom four rams allow the BOP to hold onto the drill string that is going down the (possibly deep) well - and not let go. Wouldn't want to drop a lot of expensive piping down a well.

Source: Arctic Relief Well Drilling An Oil & Gas Company Perspective

Presented at: MMS Arctic Technologies Workshop Anchorage, October 13 - 15th, 2009

Simultaneous translation: "The subsea BOPs used around the world every day have a single ram and seal - and those must work in perfect sequence or you're screwed"

---------

Page 22: The shiny new AWKS will have two rams that each can act as both a shear and a seal in one motion. With two rams, that means 100% redundancy on the critical environment-saving function. Wait a sec, does that mean that conventional subsea BOPs are a single point of failure - by design?

The shiny new AWKS rams can cut and seal in one action. There is no need for conventional automated sequencing. Ummh, does that suggest that the three-step operation of conventional BOPs relies on automated controls that might also fail?

The shiny new AWKS ram will be the ONLY shear ram that can cut and seal up to and including heavy 13 3/8" casing. Ummh, does that mean that conventional BOPs can't handle certain types of pipe?.

Simultaneous translation: "AWKS will fix all of the awful problems that are associated with the BOPs that you now use everywhere else"

---------

Page 23: The AWKS is a smaller, self-contained assembly that can be added to any standard subsea BOP. Just bolt it to the bottom (or top?) of the existing BOP and you're good to go. You have a redundant, capable BOP where none existed before. You can even use your existing BOP for its other maintenance functions that the AWKS doesn't support.

Simultaneous translation: "We now offer brakes, seat-belts and airbags as optional, dealer-installed extras"

---------

Discussion

The implications of this presentation are fascinating - for so many reasons that I am sure you can think of more to add in the comments. For now, my short list is as follows:

For the oil industry, drilling a relief well is the true gold-standard for killing a wild well. Period. BP probably appears to be winging it because they ARE winging it. The oil industry as a whole simply didn't think that it would have to stop an oil spill in any less time than the 60-90 days it would take to drill a relief well. That's in the most sensitive environment they face - the Arctic. My bet is that Shell, Exxon, Conoco, Chevron, et al wouldn't have handled GoM any better than BP.

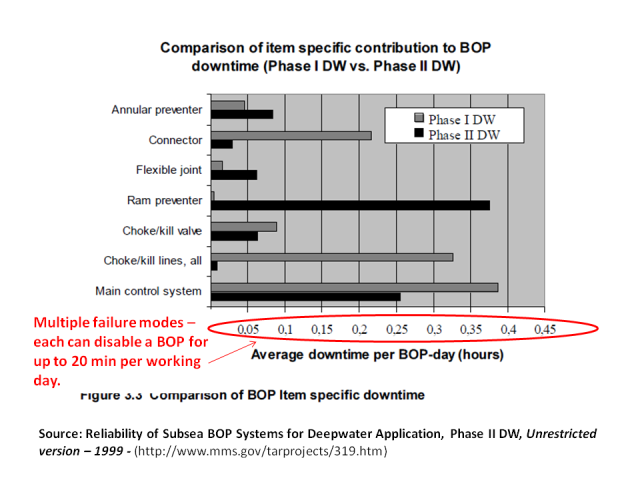

The industry has known for a loooong time that contemporary BOPs can fail. Worse, they know that the flaw is in the BOP's design. Add misuse, sloppy maintenance, or poor handling and the idea of a 'failsafe' BOP is a total joke.

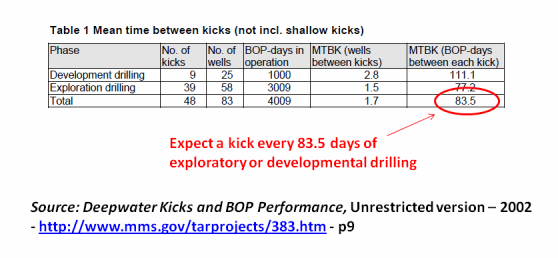

In the late 90s, MMS commissioned studies of BOP reliability in deepwater and in the face of deepwater "kicks" - the event that sank the Deepwater Horizon.

The first finding is that kicks are common. Expect one every 84 days of drilling. With hundreds of rigs in operation, kicks probably occur daily.

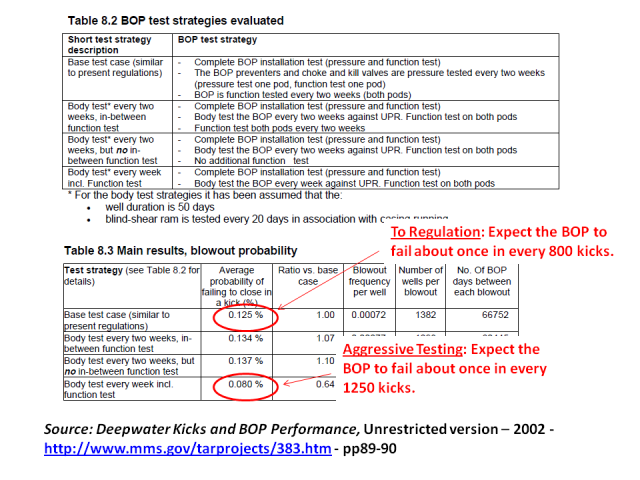

Given that, it isn't very reassuring that a BOP failure is likely to occur every 800-1200 kicks.

This might not be so bad except for the fact that the most common BOP failures involve the rams and control systems.

Now what was it that Chevron said again about the way conventional BOPs work? Oh yeah.

The BOP on the Deepwater Horizon was built by Cameron - the same vendor that worked with Chevron to design the AWKS. If Cameron designed all of these cool new features, doesn't that mean that they already knew about the contemporary BOPs' weaknesses. Why didn't they design an AWKS 10 or 20 years ago - before we went fishing for oil 10,000 ft below the surface of the ocean? Could it be that the big drillers were reluctant to pay extra for a technology that might work?

Chevron thought nothing of parading these BOP drawbacks to back their argument that, by simply fixing the more egregious problems, they should be rewarded with the freedom to drill, baby, drill wherever and whenever they want.

Picture it. Fancy conference room. Cool AV projectors. Bigshot Chevron guys showing off to other oil companies and regulators - and everyone is taking crappy BOPs as a given!

Can I be a plaintiff's attorney against BP? - Please? Pretty Please?

The Mineral Management Service thought this was so perfectly reasonable that they posted it on their conference proceedings web page. WTF? Any self-respecting regulatory body would take Chevron's assertions about conventional BOPs as grounds for subpoenas.

Let me say this again: If BOPs were any part of an airplane, the FAA would ground every plane in the world.

--- Final Thoughts ---

We cannot trust the engineering judgment of the oil industry. It's not that I think they have bad engineers. They probably have some of the smartest engineers in the world. But Chevron's presentation screams to me that, as an industry, it has totally lost the kind of basic engineering judgment that was drummed into me long ago in college. Paraphrased simply: "Everything man-made will fail sooner or later - its an engineer's Job One to make sure that it will fail in a safe, controlled manner." We can never trust a technologically dangerous industry that has forgotten that basic precept.

The Chevron presentation exhibits a fundamental arrogance that is absolutely breathtaking. It is all the more frightening because that arrogance is not blatant. It is simply assumed and reflected in virtually every bullet point. If ever I have seen a presentation that is "all about me", this is the one. Worse, to have the chutzpah to give the presentation, the Chevron crew must have known that no one would give them any pushback.

Final, Final Thought

If existing BOPs aren't reliable and a relief well is the only sure fix, I would immediately enforce two regulations before allowing ANY deepwater drilling:

- Make AWKS (or equivalent) the minimum BOP standard on all subsea wells everywhere - at least until we have a crash program to design one that is even better.

- Insist that all deepwater wells have in-place relief wells BEFORE they reach oil-bearing strata. That means that every deepwater well will probably need 2 rigs. One will drill the test well, but stop well short of oil-bearing layers. The other rig will stay just long enough to drill, test and plug a corresponding relief well. Then the relief-well rig can leave and the test well rig can proceed to the oil bearing layer. If a blowout occurs, a rig can thread the relief well, bust through the plug and kill the test well - in a few days.

Will these requirements make deepwater drilling more expensive? Yup. But it will take decades for the extra cost to come anyhere near the economic loss that we are sure to suffer just on this one GoM spill.